Wood Specialties, an esteemed custom casework and architectural millwork company based in Daphne, Alabama, has set the standard for high-quality wood finishing products and professional commercial cabinetry along the Gulf Coast for over 40 years. With a sprawling 10,000-square-foot facility, the company is well-known for its craftsmanship and reliability. When Evan Smith assumed the role of Plant Manager, he recognized the pressing need for modernization to propel the company to new heights.

Wood Specialties Automates Operations with Microvellum

Challenges with Traditional Methods

Before implementing Microvellum, Wood Specialties relied on AutoCAD to generate shop drawings. Then they followed a labor-intensive manual process for creating cutlists and G-code for their CNC and dowel machinery. This approach led to several operational challenges:

Redundant Processes: The manual workflow involved repetitive data entry, placing a heavy reliance on the accuracy of experienced staff.

Miscommunication Risks: Discrepancies between shop drawings and production instructions frequently went unnoticed, resulting in construction errors and material waste.

Drafting Bottleneck: The traditional drafting process limited the company’s capacity to handle additional projects.

Transformative Benefits of Microvellum

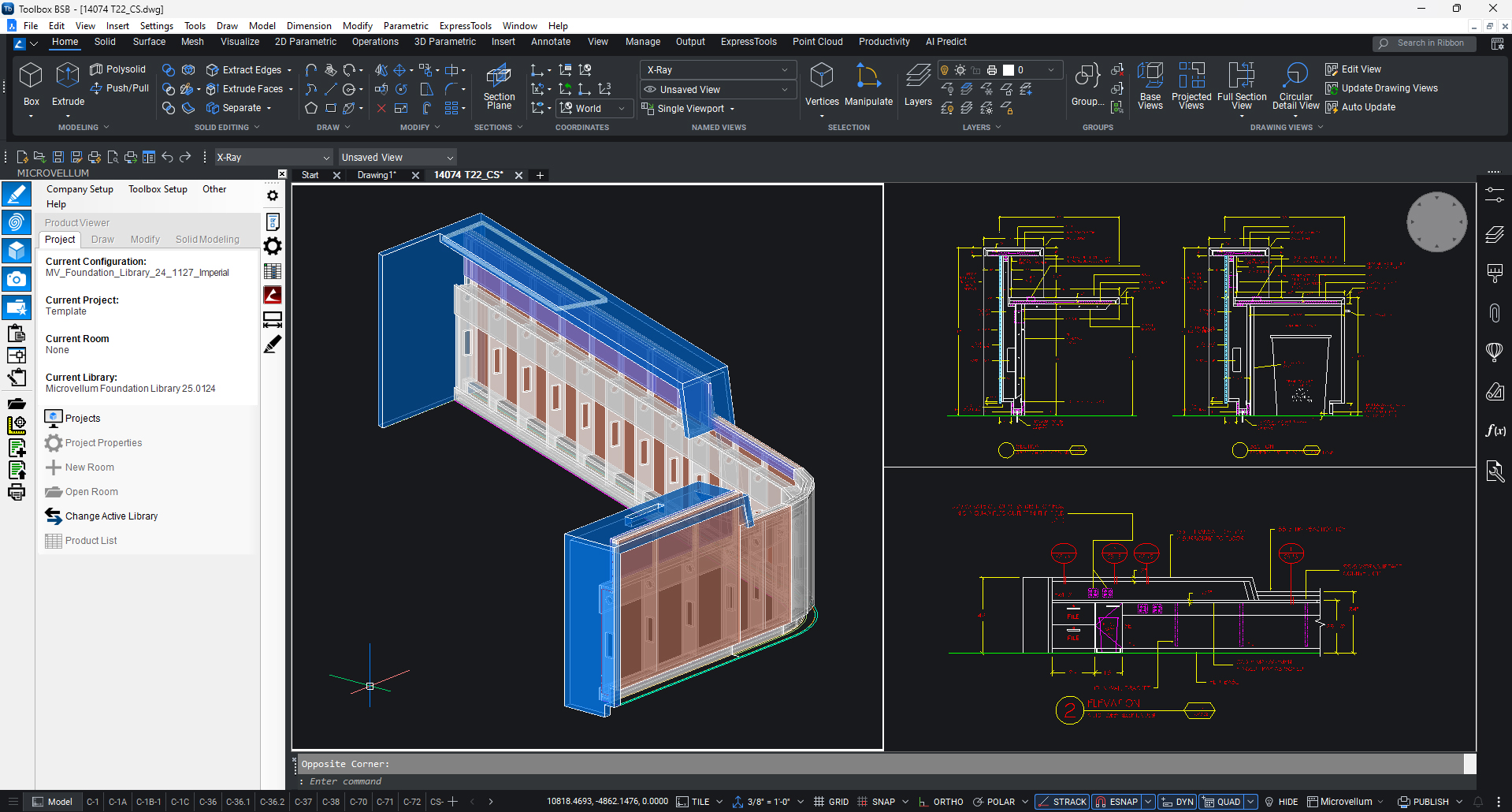

Transitioning to Microvellum was a seamless process for Wood Specialties, thanks to the software’s integration with AutoCAD. The impact was immediate and profound. Evan noted that the automation of processes virtually overnight led to a more efficient workflow, enhancing both quality and throughput by minimizing human error.

Microvellum effortlessly connected to Wood Specialties' CNC machines, including the HOMAG N300 and HOMAG D-200, ensuring that every design could be seamlessly sent to production. Additionally, the automatic generation of submittal drawings during production was a significant time-saving feature, as highlighted by Evan.

Streamlined Operations and Enhanced Accuracy

Microvellum has simplified the generation and management of work orders, providing comprehensive reports that include all necessary machine code and relevant details. Parts are labeled with barcodes, which reduces guesswork and improves accuracy in horizontal doweling. In the event of a part being damaged, it can be quickly recut using a simple elevation picture. As Evan explains,

"One of the greatest advantages of Microvellum is its requirement for thorough documentation, which has become a cornerstone for ongoing improvement."

The impact of these strategic investments has been undeniable. Since Microvellum streamlined the process by automating tedious tasks like programming and cut list generation, valuable time has been freed up. This allows Evan to focus on strengthening relationships with local customers and addressing actual bottlenecks and obstacles hindering his business growth.

With upgraded CNC machinery and automated processes in place, Wood Specialties' future goals now focus on continued growth. This includes expanding the team, branching into new markets, and pursuing other strategic improvements.

A Vision for Future Growth

Evan emphasizes that Microvellum's adaptable framework and its seamless integration with their machinery have been game-changers for the company. "The software’s seamless connection to our equipment means that our production capabilities have expanded significantly," he remarks. The efficiency gained through automation has freed up time for Evan to focus on cultivating customer relationships and addressing growth challenges.

With upgraded CNC machinery and streamlined processes in place, Wood Specialties is poised for continued expansion. The company’s future objectives include growing their team, exploring new markets, and pursuing additional strategic enhancements.

Profile

Company: Wood Specialties

Location: Daphne, Alabama, United States

Established: 1980

Employees: 15

Markets: Commercial, Medical, and Dental Cabinetry

CNC Machinery: Homag