1 / 1

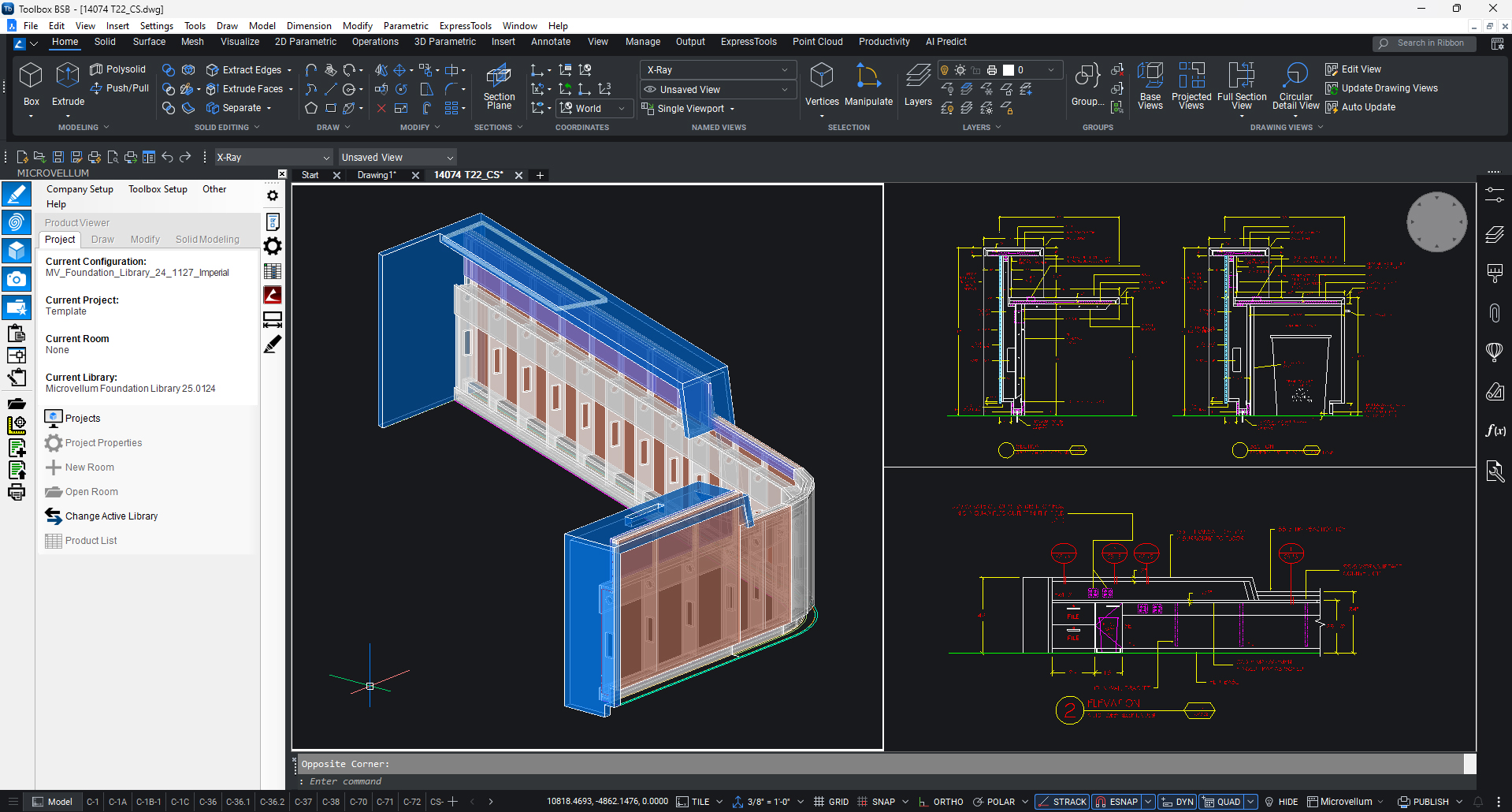

Design, engineer, and build anything from cabinets to custom interiors your way.

From kitchen cabinets and closets to commercial casework, reception areas, restaurant interiors, office furniture, staircases, and more – design, engineer, and build it your way.

Professional CAD Tools

Industry-leading solutions CAD for 2D and 3D design and drafting.

Unmatched Flexibility

Limitless customization tailored to every project and workflow.

Seamless Workflow

Seamless design-to-manufacturing with smarter material management.

Scalable Solutions

Helping woodworkers scale with better workflows, accuracy, and capabilities.

Microvellum University

We believe learning resources should be free for everyone. Explore training videos, sample projects, quizzes, community forums, and knowledge base articles to kickstart your journey.

Forging Strong Wood Industry Partnerships to Ensure Your Success

Recent News

Upcoming Events

Frequently Asked Questions

How does Microvellum help with drafting cabinet designs?

Microvellum's Toolbox software is built for AutoCAD and BricsCAD, allowing you to create detailed and precise architectural submittal drawings and shop drawings for residential and commercial cabinetry and so much more. It automates much of the drafting process, reducing the time spent on repetitive tasks and ensuring accuracy in dimensions and detailing.

Can I create shop drawings for custom cabinets in Microvellum?

Yes, Microvellum's Toolbox software allows you to produce fully customized shop drawings for custom cabinetry projects. You can adjust dimensions, materials, and hardware to meet the specific needs of the project, and the software automatically generates accurate, detailed drawings for production.

How flexible is Microvellum when it comes to custom cabinet design?

Microvellum is extremely flexible, offering tools to modify existing product libraries or create entirely custom designs. You can adjust all aspects of your cabinetry, including materials, construction methods, hardware, and finishes, ensuring your designs meet specific client needs.

Can I use Microvellum to visualize my designs before production?

Yes, Microvellum's Toolbox software allows you to create detailed 3D models of your cabinet designs. You can visualize materials, hardware, and finishes in the design phase, ensuring your client can see what the final product will look like before manufacturing begins.

How does Microvellum assist with cost estimation and project bidding?

Microvellum has built-in tools for creating detailed cost estimates. Calculations for material, hardware, labor, and overhead costs, allow you to generate accurate project bids. This helps ensure profitability while maintaining competitive pricing.

Can Microvellum provide detailed material usage reports for estimating purposes?

Yes, the Microvellum generates detailed reports, including material usage and optimization, cut lists, and pricing, ensuring that estimates are based on accurate data. This helps you better plan for material needs and reduce waste.

What CAD software does Microvellum Toolbox integrate with?

Microvellum Toolbox integrates with both BricsCAD and AutoCAD, delivering powerful design, drafting, and engineering tools on the CAD platform that fits your workflow. Whether you choose BricsCAD or AutoCAD, Toolbox provides the precision, performance, and intelligent automation you need to take projects from concept to production.

Does Microvellum integrate with INNERGY ERP software?

Yes, Microvellum integrates with INNERGY ERP. Our open architecture makes it easy to connect with systems like INNERGY, enabling a seamless flow of data between engineering and operations. From bill of materials and cut lists to purchasing, job costing, and scheduling, this integration helps eliminate manual data entry, reduce errors, and keep your teams aligned—from design through delivery.

How does Microvellum handle cabinet construction methods and hardware?

Microvellum includes a robust library of construction methods and hardware options, which can be customized to meet your specific preferences. You can adjust joinery, hardware types, and assembly methods, and the software will automatically reflect these changes in the engineering and production data.

Can I customize the engineering specifications for different cabinet projects?

Absolutely. You can modify engineering specs to fit different project requirements, including cabinet structure, hardware, materials, and construction methods. These specifications are then used to generate shop drawings, material lists, and production data.

What types of products can be built using Microvellum?

Microvellum is highly versatile and can engineer a wide range of products beyond just cabinetry. You can design and manufacture kitchen cabinets, closets, office furniture, store fixtures, millwork, and other custom wood products. Whether you need to engineer standard cabinets, complex curved structures, or entirely custom furniture, Microvellum provides the tools to create detailed designs and generate accurate manufacturing data for a variety of wood products.

Is Microvellum useful for cabinet makers who don’t use CNC machinery?

Yes, even without CNC machines, Microvellum streamlines the design and engineering processes. Generates accurate cut lists, assembly instructions, and material reports, making it easier to manage manual manufacturing workflows and reduce errors in production.

How does Microvellum integrate with CNC machinery for cabinet production?

Microvellum is designed to work seamlessly with CNC machines. Generate machine-ready code directly from your designs, optimizing material usage and automating the tool pathing and machining processes. This ensures efficient production with minimal manual intervention, increasing accuracy and reducing waste.

Does Microvellum offer subscription pricing?

Yes, Microvellum software is available through an annual subscription. This gives you full access to all features, updates, and technical support for an entire year—with the flexibility to pay annually or in monthly installments. Your subscription ensures uninterrupted service, continuous improvements, and access to new features as they’re released.

Does Microvellum offer free training?

Yes, Microvellum offers free training through Microvellum University, an online platform designed to support users at every skill level. The University provides access to free instructional videos, sample projects, and quizzes, allowing users to learn at their own pace. These resources cover foundational concepts, advanced techniques, and practical workflows to help users get the most out of their software. Whether you're just getting started or looking to deepen your expertise, Microvellum University is a great place to begin—completely free of charge.

Let's Build Something Extraordinary

Dc