The Microvellum Moment: One Platform for the Entire Shop

Microvellum became the platform SMW needed to tie everything together. Today, the company runs nine Microvellum operators across drafting, engineering, custom product design, and purchasing.

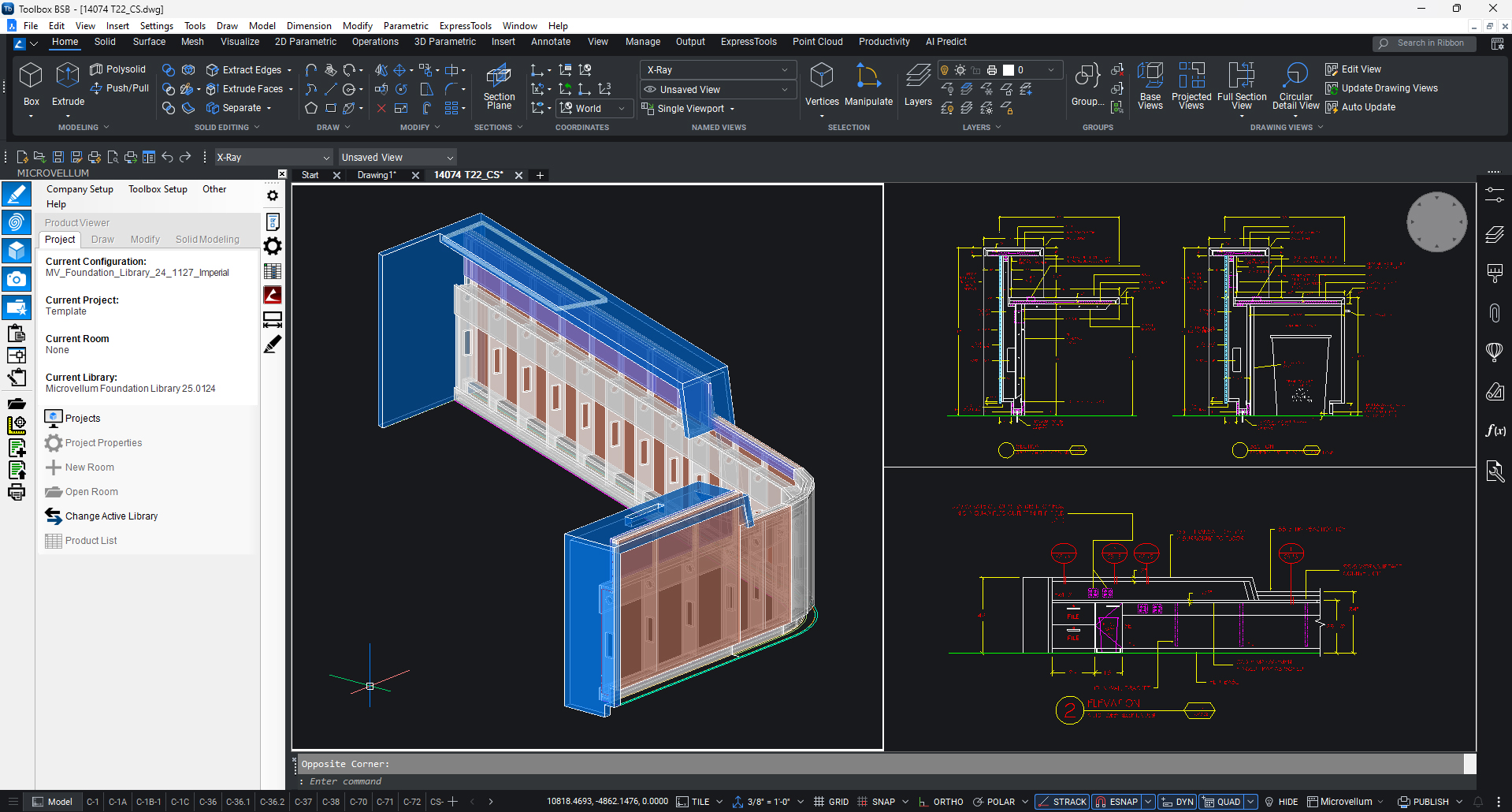

Instead of engineering the same information multiple times in different systems, SMW now builds parametric product models that drive the entire workflow. Submittal drawings, casework engineering, cut lists, reports, and CNC-ready data are all generated from the same source, backed by a shared SQL database.

Multiple machines can be fed simultaneously without redundant programming, allowing engineering and production to move forward in parallel rather than in sequence.

Purchasing, Bottlenecks, and Complex Production

Purchasing is now directly connected to engineering. SMW’s purchaser works inside Microvellum, using automatically generated bills of materials and hardware requirements that are driven by real engineering data, not manual interpretation. Order schedules are clearer, data extraction steps are eliminated, and information flows directly from engineering to the shop floor.

What once took days to process and clog the floor now moves through the system in a single day.

SMW builds everything from institutional casework to high-end residential projects with face frames, inset doors, and mixed-material commercial interiors. Microvellum supports this diversity by allowing the team to standardize construction logic while still accommodating custom details, specialty assemblies, and non-standard materials without sacrificing consistency or speed.

Transformative Results Across Throughput, Accuracy, and Visibility

SMW’s shift to Microvellum has produced measurable improvements across the business.

By moving from siloed systems to a single source of engineering truth, throughput increased dramatically. Backlogs that once overwhelmed the shop floor have been eliminated, and projects now move through engineering and production with far fewer interruptions.

Accuracy has improved as well. Automated machining data and standardized product logic reduce human error and eliminate the need for manual CNC programming. With nine operators working inside the same platform, SMW can handle more projects while maintaining consistent documentation and predictable outcomes.

Connected workflows also provide better visibility. Engineering, purchasing, and production teams are all working from the same data, making it easier to plan workloads, anticipate material needs, and respond quickly to changes.

Culture, Collaboration, and the Next Generation of Manufacturing

SMW’s collaborative culture remains a key part of its success. Engineers, installers, and fabricators stay closely connected to each other’s work, and Microvellum reinforces that culture by giving every department access to accurate, consistent engineering data.

Sam Stafford, a 25-year veteran who remembers Microvellum’s earliest versions, sees the current environment as a fundamental shift.

“Today everything is driven from one system. Equipment is networked, data is clean, and every part of the shop is working from the same source, Microvellum.”

The platform has become a core tool that allows SMW to take on more complex work with the same workforce, while giving new hires a modern, learnable system they can grow into.

SMW’s next evolution is focused on operational insight. With consistent engineering data flowing through Microvellum, the team is beginning to explore how that information can support smarter, faster decisions at the business level.

Looking Ahead: Moving Toward a Data-Driven Operation

SMW’s next evolution is focused on operational insight. With consistent engineering data flowing through Microvellum, the team is beginning to explore how that information can support smarter, faster decisions at the business level.

As SMW continues expanding its capabilities, Microvellum provides a reliable foundation for greater visibility, better planning, and future investment in connected systems.