To maintain their competitive edge and continue taking on increasingly complex projects, the company needed a solution that would enhance efficiency, streamline their processes, and ensure scalability without compromising their signature attention to detail. Simpson Liddard now leverages Microvellum to meet these demands, allowing them to deliver exceptional results on a larger scale.

Strategic Investments in Bespoke Interior Fit-Outs: Simpson Liddard’s Success with Microvellum

Scaling for Complex Bespoke Interior Fit-Outs

Simpson Liddard’s expertise in bespoke interior fit-outs made them a sought-after partner for high-end projects, but as demand grew, their traditional methods couldn’t keep up with the increasing complexity. Managing intricate workflows with outdated processes began to slow production, limiting their ability to take on larger jobs.

“We were known for our attention to detail and craftsmanship, but as our workload grew, our existing processes couldn’t handle the complexity of bespoke projects,” said Matt Comer, Owner of Simpson Liddard.

Embracing Technology with Microvellum

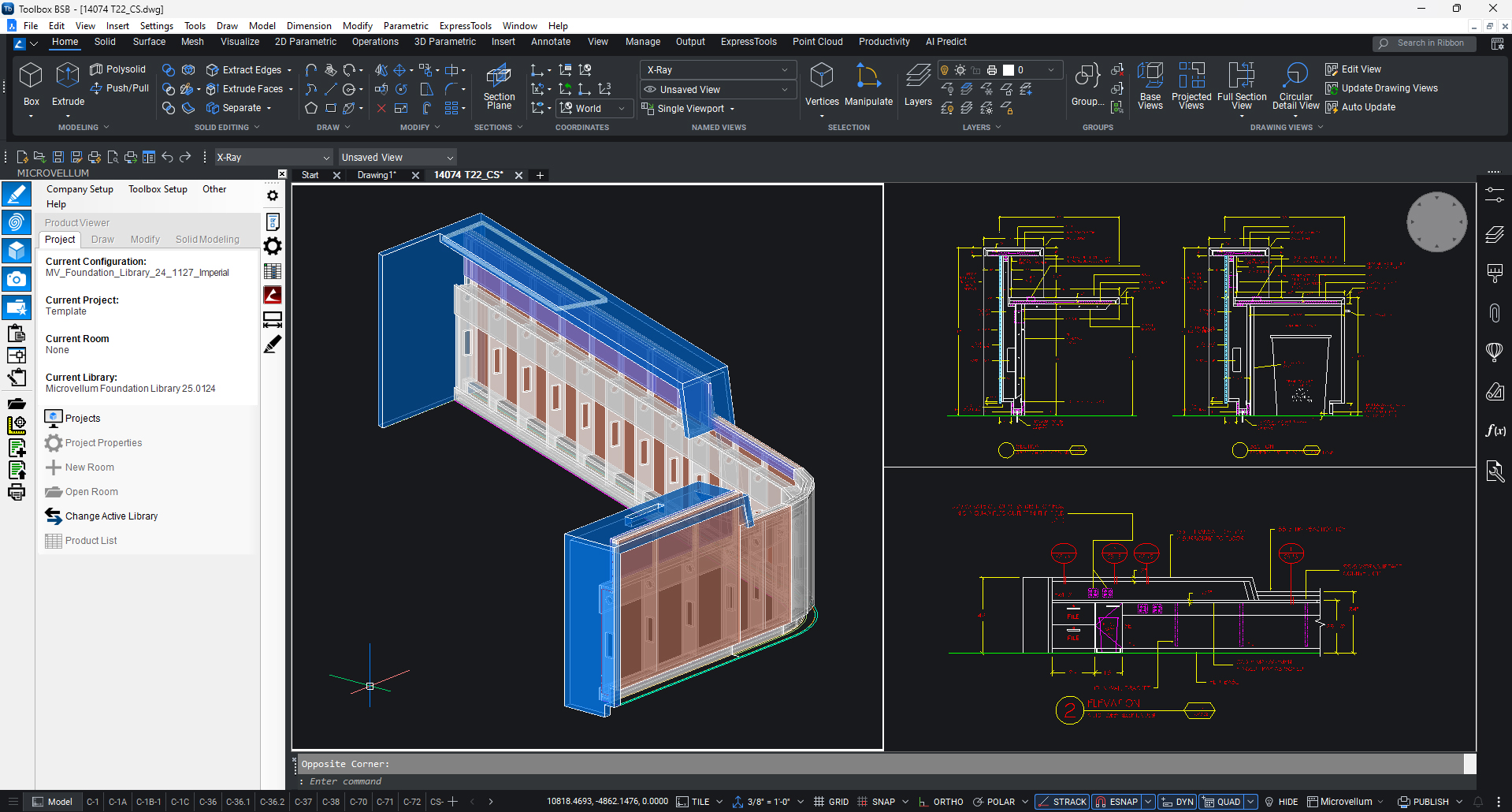

Microvellum's AutoCAD integration streamlined their workflow, allowing the drafting team to effortlessly design everything from simple cabinetry to the most intricate joinery pieces. Features like automated drafting and 2D/3D drawing capabilities significantly reduced manual work and ensured design accuracy.

Beyond design, the true power of Microvellum lies in the production tools like material optimization, CNC machine code generation, and detailed reporting. This one-stop-shop approach eliminated communication gaps between design and production, ensuring projects flowed smoothly from concept to completion. As Danny Liddard, from Simpson Liddard, reflects, "Microvellum has been instrumental in tackling complex joinery with efficiency. The software's flexibility allows us to quickly customize cabinetry designs while ensuring flawless execution.”

“With Microvellum, we’ve been able to scale our operations while maintaining the level of quality our clients expect. It’s been a game-changer for our bespoke interior fit-out projects,” Comer added.

Achieving Efficiency and Quality in Bespoke Joinery

Since implementing Microvellum Software, Simpson Liddard has seen substantial improvements in both efficiency and project output. The streamlined workflows have enabled the company to take on more complex bespoke interior fit-outs, all while reducing lead times and increasing profitability.

Key benefits include:

Faster Project Turnaround: Microvellum’s automation features reduced the time spent on manual tasks, allowing the team to complete projects faster.

Improved Accuracy: The software’s integration between design and production reduced errors, ensuring that every bespoke interior fit-out met exact specifications.

Scalability: Simpson Liddard can now handle larger, more intricate projects without sacrificing quality, positioning them as a leader in the bespoke interior fit-out market.

Driving Future Innovation in Bespoke Interior Fit-Outs

With Microvellum Software at the core of their operations, Simpson Liddard is well-positioned to continue delivering innovative, high-quality bespoke interior fit-outs for their clients. Their investment in technology has not only enhanced their productivity but also strengthened their reputation as a top-tier provider of custom interior solutions.

“The decision to invest in Microvellum has allowed us to grow our business while continuing to meet the unique demands of bespoke interior fit-outs. We’re excited about what the future holds,” said Comer.

By adopting Microvellum Software, Simpson Liddard has successfully scaled their bespoke interior fit-outs, delivering complex projects more efficiently without compromising on quality. Their strategic investment in technology is a testament to their commitment to innovation and craftsmanship in the UK’s interior design industry.

Profile

Company: Simpson & Liddard

Location: Essex, England, United Kingdom

Established: 2021

Employees: 10

Markets: Residential and commercial joinery

CNC Machinery: Felder