Struggling with rising project complexity and time-consuming manual processes, Matt Comer, owner of Homestead Cabinets, realized his team needed a more efficient solution to maintain their high standards and meet growing demand. Despite over 30 years of delivering award-winning craftsmanship in Mornington Peninsula, Australia, outdated methods were slowing them down.

After seeking advice from a trusted friend already using Microvellum, Matt was intrigued. A few demos and a firsthand look at its capabilities convinced him that Microvellum was the game changer Homestead Cabinets needed. "Microvellum was exactly what we needed," Matt affirmed.

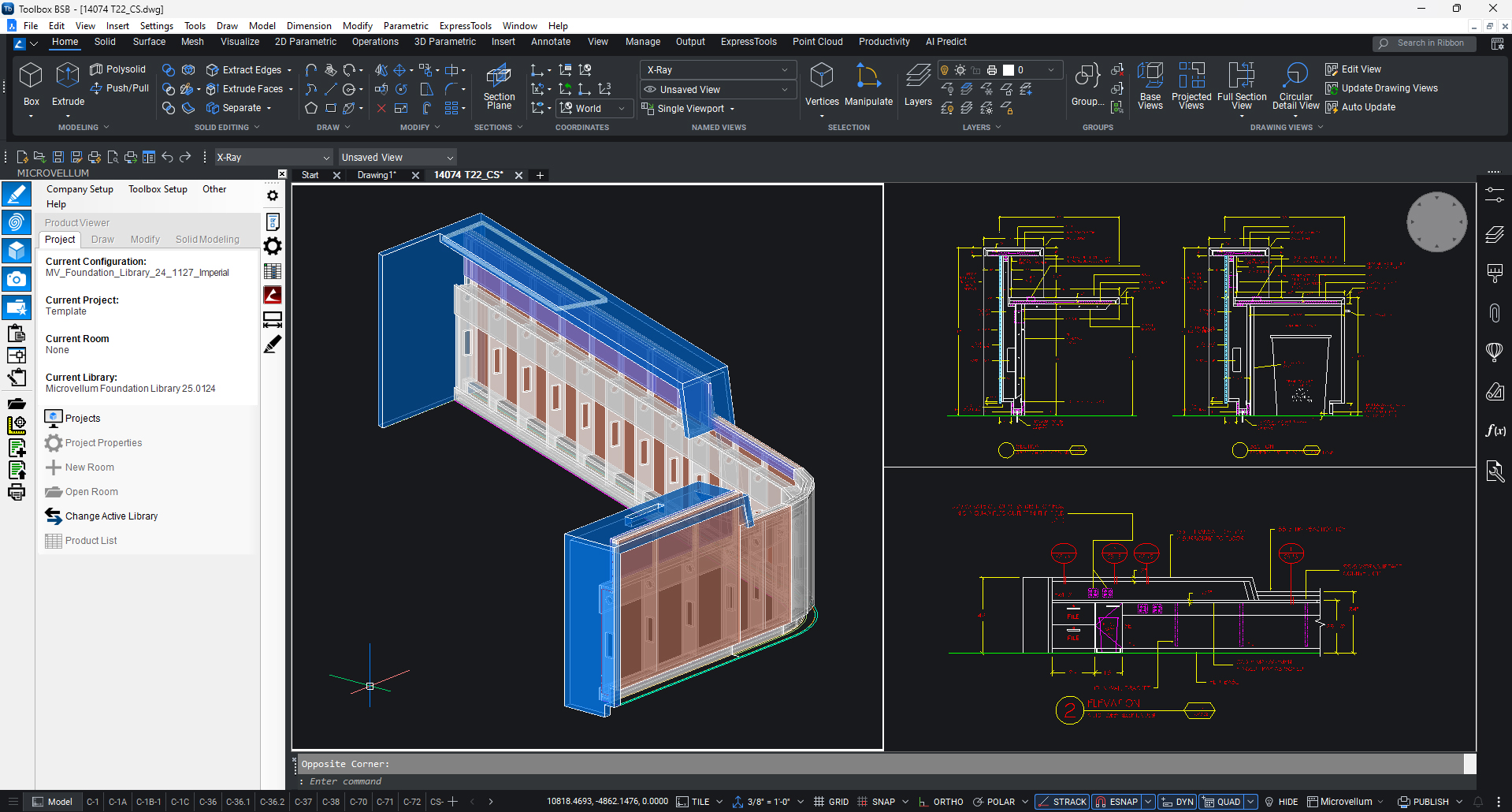

Homestead Cabinets Uses Microvellum for Efficient Kitchen Cabinet Design & Manufacturing

The Challenge: Outdated Processes Slowing Production

Homestead Cabinets had relied on traditional methods like panel saws and manual cutting for years. While these methods had served them well, they were becoming inefficient as the company took on more complex projects. "The old panel saw edgebander was the trick, but CNCs sounded expensive," Matt explained. However, the time spent manually cutting and assembling cabinetry was no longer feasible, especially as client demands grew and deadlines tightened.

The Solution: Microvellum and CNC Integration as a Game Changer

When Matt decided to invest in a CNC machine, he knew that pairing it with Microvellum would be key to maximizing its potential. The combination of CNC technology and Microvellum’s software turned out to be, in Matt’s words, "an absolute game changer." What once took weeks could now be completed in a fraction of the time. The shift from manual work to automated precision dramatically sped up operations and allowed Homestead Cabinets to handle projects that would have been far too time-consuming before.

"Having Microvellum actually saves a lot of time out on the floor,” Matt shared. The software’s ability to integrate seamlessly with CNC meant that once a design was drawn, the CNC machine could immediately begin cutting, allowing the team to jump straight into production.

Problem Solved: Tackling Complex Projects with Ease

One of the biggest challenges Homestead Cabinets faced was handling intricate, custom designs that required extensive manual labor. These projects were not only difficult to scale but also took a considerable amount of time. Matt noted, "If you're doing them manually, gosh, it would take some time. Having Microvellum and putting them to CNC makes so much quicker time to it."

With Microvellum, Homestead Cabinets could now execute complex designs with speed and precision, boosting their productivity and enabling them to take on more challenging projects without sacrificing quality.

A Competitive Edge: Winning Clients with Detailed Designs

Another key benefit of Microvellum was its ability to produce highly detailed project plans, which became a crucial factor in winning over clients. "Microvellum is a big part of how we pick up work," Matt explained. Designers and clients were often amazed at the level of detail Homestead Cabinets could achieve, frequently saying, "Look how good that is. We can't do that."

This attention to detail became a key differentiator for the company, helping them attract new clients and retain existing ones by consistently delivering impressive, customized designs.

Seamless Integration and User-Friendly Design

Adopting new software can be daunting, but for Homestead Cabinets, the transition to Microvellum was smooth. "We worked together through it, and we were up and about really quickly," Matt recalled. The software’s user-friendly interface made it easy for the team to adapt and manage even complex projects with ease.

The team could view and troubleshoot designs in both 2D and 3D formats, ensuring that everyone was aligned throughout the production process. "If something's quite hard, I'll detail it on a plan from Microvellum, and it all becomes quite easy to do," Matt said, underscoring how the software had streamlined their operations and reduced time spent troubleshooting.

The Results: Increased Profits and Faster Turnaround

The results of implementing Microvellum were clear: increased profits and faster project timelines. "Profits just skyrocketed, and the quickness was amazing," Matt shared. The software enabled Homestead Cabinets to take on more work without adding to their workforce, allowing them to grow without sacrificing their reputation for quality.

Builders who had previously expected long lead times were frequently surprised by the speed and precision of Homestead Cabinets' work. Matt recounted how clients would say, "What are you doing here? Thought it'd take months." But with Microvellum, the team was able to meet—and often exceed—expectations, delivering projects faster than ever.

The Secret to Their Success: Microvellum

Today, when clients ask how Homestead Cabinets manages to deliver such complex projects with unmatched speed and quality, Matt has a simple answer: "The secret is Microvellum."

Profile

Company: Homestead Cabinets

Location: Dromana, VIC Australia

Established: 1998

Factory: 720 sqm

Employees: 7-10

Markets: High-End Residential Cabinets