RMEISH, an architectural joinery specialist based in Thomastown, VIC, has built its reputation by delivering high-end joinery solutions for both residential and commercial projects. From intricate kitchens and bathrooms to large-scale commercial fit-outs, the company consistently tackles challenging projects. However, managing tight deadlines, maintaining accuracy, and ensuring craftsmanship posed significant hurdles in the fast-paced Melbourne construction industry. To overcome these challenges, RMEISH invested in Microvellum’s AutoCAD-based design and manufacturing software, revolutionizing its processes.

RMEISH Streamlines Complex Joinery Projects with Microvellum’s AutoCAD-Based Software

Problem: Tight Deadlines and Complex Designs in Melbourne’s Construction Industry

In the competitive construction landscape of Melbourne, builders face intense pressure to deliver high-end work within tight timeframes. As Operations Manager Tony Mansour explained, “Melbourne runs on an 80-hour work week. Builders sign on for jobs in ridiculous timeframes... joinery is one of the most heavily used trades. You walk into any building, and the first thing you see are the floors, the ceiling, and the joinery—it’s got to be right.” For RMEISH, this meant balancing speed with precision and ensuring that each piece of joinery met the highest standards.

Solution: Microvellum’s AutoCAD-Integrated Software for Joinery Precision

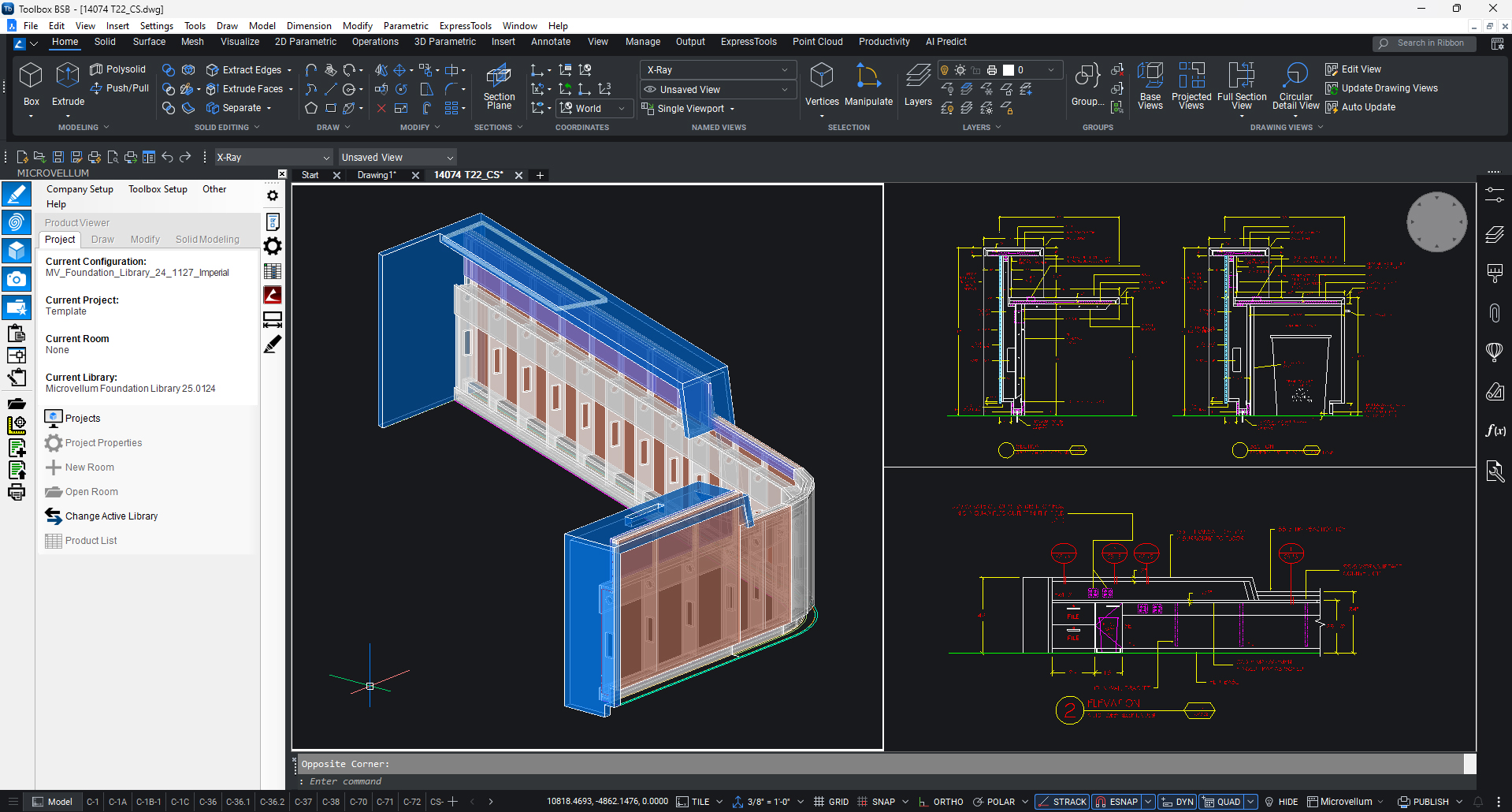

To address these challenges, RMEISH adopted Microvellum, an AutoCAD-based software platform built for precise design and streamlined manufacturing. Tony Mansour highlighted that before Microvellum, their workflow involved multiple software programs that required double and triple-handling information. This manual approach increased the likelihood of errors and delays. Now, with Microvellum, RMEISH has integrated its processes into one platform, significantly improving both accuracy and efficiency. “Once it’s drawn and you’ve got your dimensions, nothing changes. Microvellum eliminates second-handling errors and streamlines the process.”

Increased Efficiency, Reduced Errors, and Improved Client Communication

The implementation of Microvellum’s software has had a profound impact on RMEISH’s operations. Not only has it reduced production time, but it has also improved accuracy, cutting down rework and waste. The software integrates directly with CNC machinery, allowing for seamless automation of tasks such as cutting and drilling. “What used to take us two hours draft now takes just 30 minutes,” Tony explained. The software optimizes complex designs with a simple click, improving production efficiency without compromising quality.

Additionally, Microvellum’s 3D visualization tools have greatly enhanced communication between RMEISH, architects, and clients. This allows for more transparent design reviews and faster project approvals. “We can easily mark up details and show architects a 3D image of what we’re talking about,” Tony said, highlighting how this clarity reduces revisions and ensures timely project completion.

Another key feature that has streamlined RMEISH’s workflow is the ability to create custom cabinet libraries within the software. These libraries store frequently used designs, enabling quick modifications and consistency across multiple projects. General Manager Jessica Savic noted, “When someone new joins our team, they’re always surprised by how quickly something can go from being drafted on Microvellum to being delivered.”

Driving Future Success: Microvellum Fuels Growth and Innovation at RMEISH

Looking ahead, RMEISH remains confident in Microvellum’s ability to support their growth. The software has pushed the company forward, helping them meet tight deadlines and deliver increasingly complex projects. “The more we invest in the program, the more we see in return,” Tony emphasized. With its ability to simplify complex joinery, enhance accuracy, and speed up production times, Microvellum will remain a cornerstone of RMEISH’s operations as they expand their portfolio of high-end joinery projects.

As RMEISH continues to grow, Microvellum’s advanced features, such as CNC integration and custom libraries, ensure that the company is well-prepared to handle the demands of the fast-paced Melbourne construction industry. By streamlining processes and reducing human error, RMEISH can focus on delivering top-quality joinery that exceeds client expectations.

Profile

Company: Rmeish Joinery

Location: Thomastown, VIC Australia

Established: 1984 (Lebanon)

Re-Established: 1997 (Australia)

Employees: 11-50

Markets: Architectural joinery, kitchens, bathrooms, wardrobes, commercial fitouts.