Client Story

Interscapes Uses Microvellum & RiseUp Labels to Connect Data with Automation for Greater Efficiency

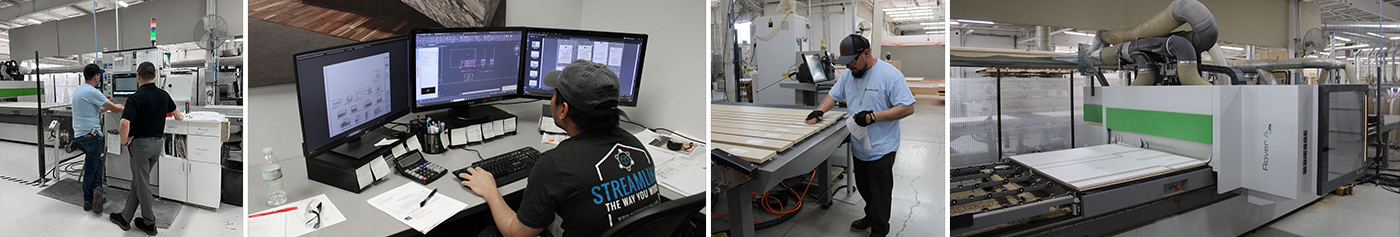

Founded in 1987 by Ron Lyrek, Interscapes has grown from a one-man cabinet shop into a 28,000 sq. ft. architectural woodworking facility with 45 employees in Minneapolis, Minnesota. Over nearly four decades, the company has built a reputation for high-quality commercial interiors and reliable, on-time delivery.

But growth brought challenges. As Interscaptes expanded, multiple facility moves created strain, and production bottlenecks slowed progress. Skilled labor was increasingly difficult to find. Instead of expanding yet again, Ron took a bold step: introduce the Toyota Lean Production System and shift the company from “working harder” to “working smarter.”

As Ron explains: “We’ve always invested in equipment and software, but the real opportunity was empowering our people to find solutions and create efficiency.”

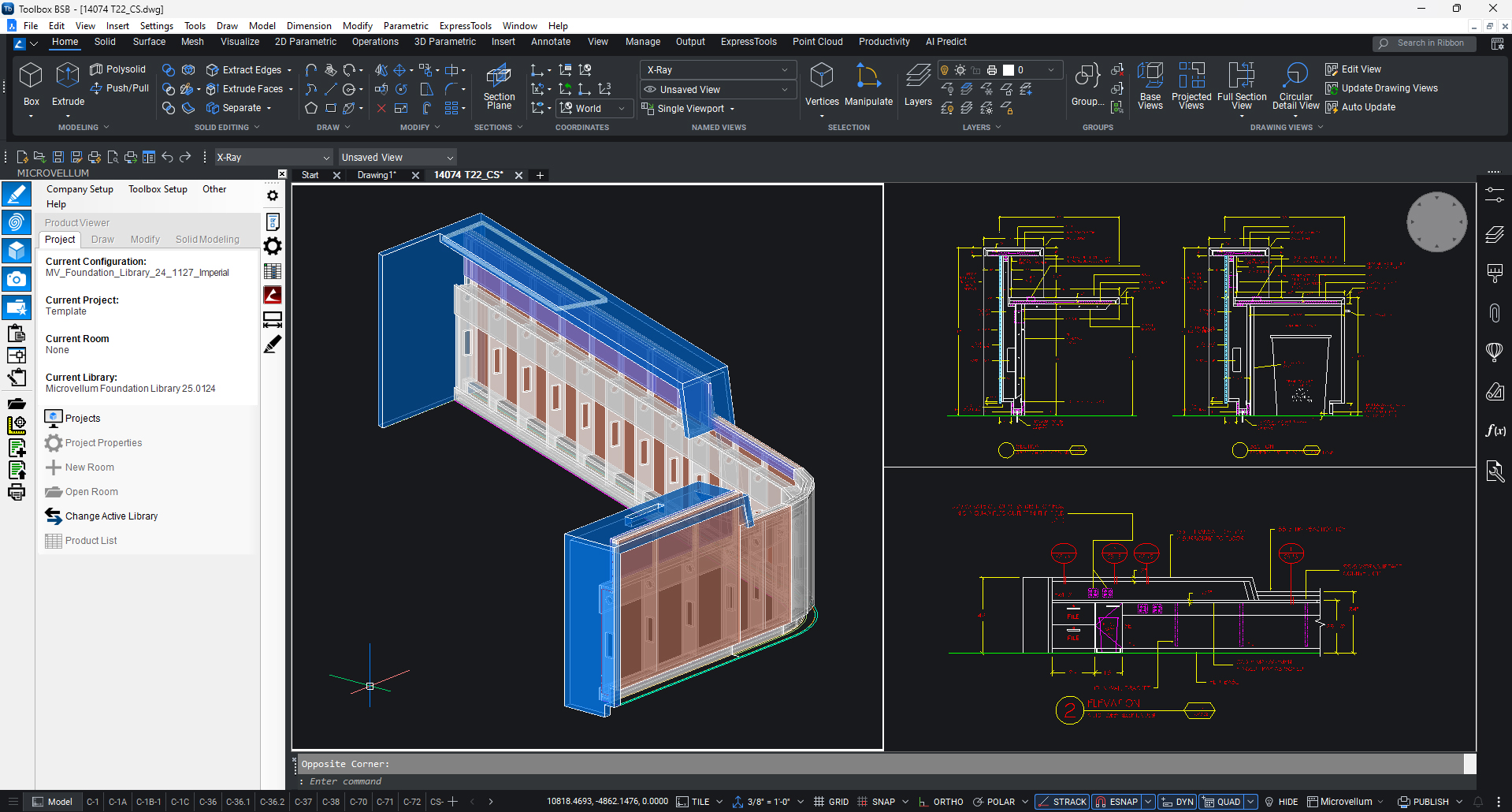

From Early Adoption to Smart Integration

Interscapes became an early adopter of Microvellum nearly 20 years ago, recognizing its potential to unify design and manufacturing. Today, Microvellum drives an integrated workflow, sending smart data directly to their Biesse machinery including Rover B CNC routers, Rover machining centers, a Winstore storage system, a Roxyl edge bander, and an Omal machine.

Microvellum’s smart data, integrated with Biesse’s advanced machinery and RiseUp’s advanced labels, creates the perfect formula for Interscapes’ productivity, ensuring every job flows from design to delivery without disruption.

This combination has transformed production capacity:

Microvellum Labels: Microvellum-generated labels eliminate manual entry errors by printing part, edging, and job details directly at the machine.

Winstore Flow: Automates material staging, boosting throughput to 8 to 10 sheets per hour compared to 4 to 6 manually. This allows Interscapes to operate as if they had a third router.

RiseUp Labels: Stay in place through every step but peel away cleanly, eliminating relabeling and residue.

Data flows through our shop without interruption, keeping production synchronized and reducing bottlenecks.

How Microvellum & RiseUp Support Smarter Work

With capabilities like automated cut lists, detailed shop drawings, intelligent nesting, barcoding, and seamless CNC integration, Microvellum provides Interscapes with a fully connected and data-driven workflow. By eliminating manual steps and reducing rework, the software delivers the precision, speed, and manufacturing efficiency needed to keep production moving without bottlenecks.

Paired with RiseUp Labels, Interscapes has streamlined its CNC labeling automation process. Labels now stay firmly in place through machining, edging, and assembly but peel away cleanly with no residue—saving valuable time, protecting surfaces, and improving throughput across the shop. This upgrade not only enhanced production accuracy but also increased employee satisfaction by removing one of the most frustrating bottlenecks on the floor.

Empowering People, Driving Profits

Technology created efficiency, but people turned it into results. Through the Great Game of Business management system of open-book management and gain-sharing, employees are empowered to act like owners. Teams created “mini-games” to pinpoint sources of rework and part movement, then turned those wins into software and process updates. In Microvellum they refined nesting rules, adjusted machining parameters, and updated label templates so the right details print at the right station. The result was a 50 percent reduction in errors and smoother flow across the shop.

As Ron reflects: “We used to think efficiency was just about equipment. Now we see it’s about giving our team the tools and ownership to make improvements every day.”

A Trusted Partner, A Clear Mission

Through lean manufacturing, advanced technology, and a culture of empowerment, Interscapes has built more than cabinetry; they have built a reputation as a leader in architectural woodworking. Their ability to adapt, grow, and deliver with consistency has kept them at the top of their market for nearly four decades

“My team has helped me to accomplished many of my dreams; it’s time to help others accomplish theirs.” – Says Ron as he looks to the future and what he wants to achieve for his next chapter.

Microvellum is proud to play a part in that journey. By connecting design to manufacturing with precision tools, automated data, and smart labeling, Microvellum helps Interscapes work smarter, not harder. That partnership enables the company to scale capacity, reduce errors, and maintain its near-perfect record of on-time delivery.

At a glance:

Employees: 45

Facility Size: 28,000 sq. ft.

Annual Sales: Projected $8M in 2025

Key Tools: Microvellum software, RiseUp Labels, Biesse machinery

Impact:

50% reduction in rework through process improvements and targeted software updates.

Increased machining throughput from 4- 6 to 8-10 sheets per hour.

Ability to grow 25 percent without additional staff.

Doubled profit per dollar through employee ownership.