Client Story

How Philip Clay Designs Optimized Manufacturing with the Right Software

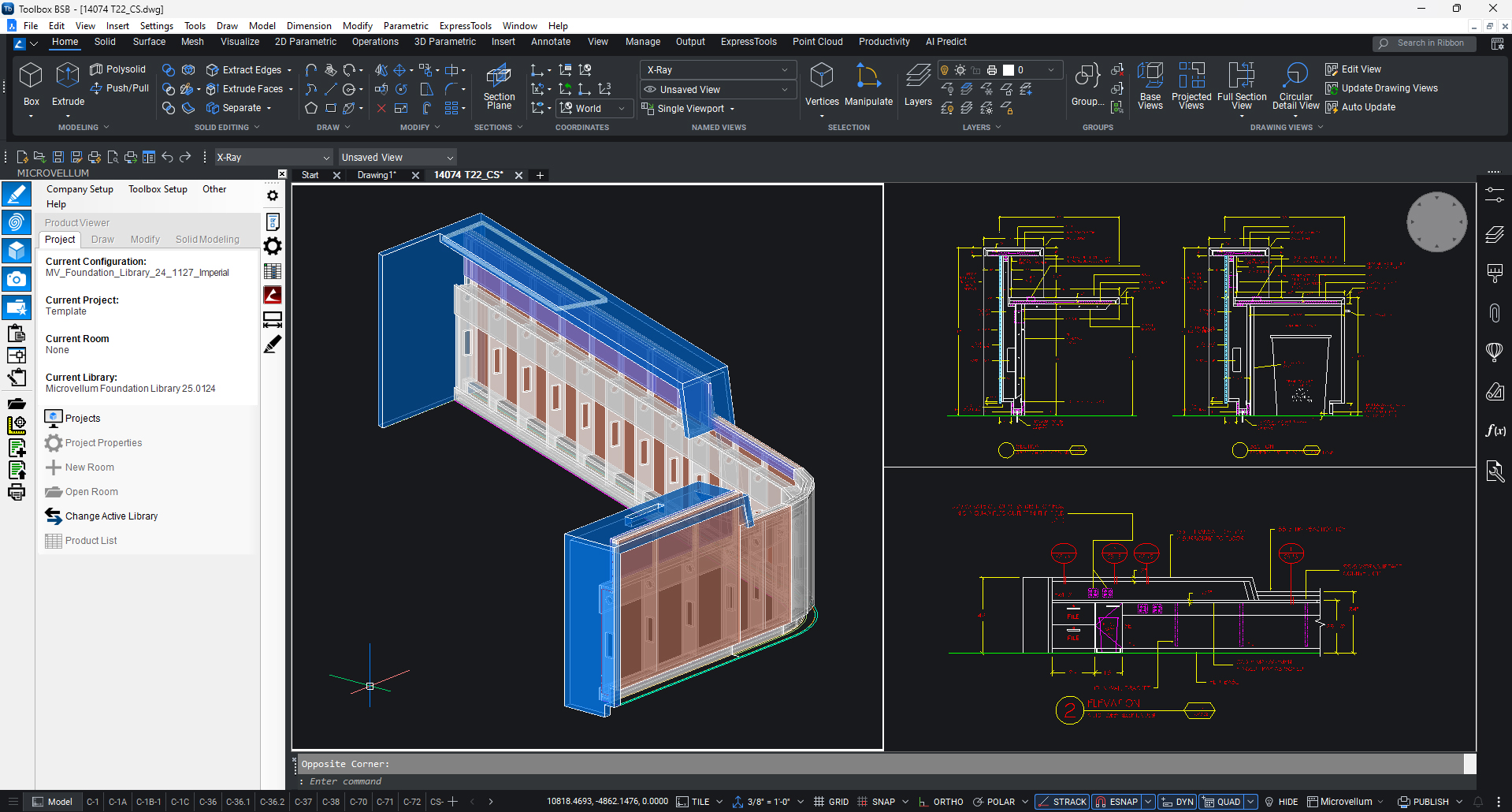

Searching for software that seamlessly integrated with AutoCAD and streamlined their manufacturing process, Philip Clay Designs invested in Microvellum. The company, founded by husband and wife Philip and Keighley Clay in the South of England, is a fully bespoke British kitchen cabinetry shop known for its craftsmanship and attention to detail.

Phil always knew he wanted to run his own business. He got his start building fine furniture in his parents’ garage, gradually growing the operation into a 6,500-square-foot shop that now supports a team of 15. He’s focused on creating bespoke, one-of-a-kind projects—an approach that reflects his passion for craftsmanship and precision. While some manufacturers specialize in high-volume production, Phil has carved out a niche by offering highly bespoke work that’s tailored to each client’s vision.

However, as demand grew, the team recognized that their traditional methods were limiting their ability to scale efficiently. They needed the right tools to bring their clients' ideas to life—faster, with fewer errors, and without compromising on quality. With a strong desire to improve workflows, reduce costly turnbacks, and eliminate manual bottlenecks, their search for a powerful and flexible software solution became essential.

Moving forward, the team was also focused on expanding their capabilities—investing in a Biesse Rover AS nesting machine, automating key departments, and growing their team. They aimed to break into the commercial sector, take on more high-end residential clients, and accelerate their growth. To do so, they needed a solution that not only integrated with AutoCAD but also supported automation, collaboration, and a higher level of production efficiency.

Microvellum proved to be the solution Philip Clay Designs was searching for—a scalable platform that integrated seamlessly with AutoCAD and offered the automation, customization, and support they needed to transform their operation. “Microvellum has helped us standardize our processes and streamline the way we work, allowing us to grow much faster than we anticipated,” said Philip Clay, owner of Philip Clay Designs.

“It benefits every department, from ordering to the shop floor, helping us produce furniture more efficiently and with fewer errors.”

What stood out to the team was Microvellum’s ability to adapt to their unique workflows while providing robust training and support throughout the implementation.

From improved workflows and reduced errors to faster production and smarter scaling, the platform is enabling them to grow sustainably, achieve their goals, and position themselves as a leader in bespoke British cabinetry.

With a clear plan in place and the right technology behind them, the team is now empowered to scale their business with confidence—delivering quality, efficiency, and precision with every project.

Looking ahead, Philip Clay Designs is leveraging Microvellum to help drive the next phase of their expansion. With the software’s seamless integration with AutoCAD, built-in support for CNC machining, and powerful tools for automating production, they’re laying the groundwork to scale their business strategically. “Microvellum has proven to be an invaluable tool in our growth and operational success,” said owner Philip Clay. It not only helps bring their clients’ ideas to life with precision and efficiency, but also supports their plans to break into the commercial sector—particularly boutique hotels—while maintaining their foothold in the high-end residential market. By streamlining ordering, reducing errors, and accelerating production on the shop floor, Microvellum is helping the team prepare for key investments, including an edge bander, an automated finishing department, and expanding their team. With these tools in place, Philip Clay Designs is aiming to increase turnover and continue growing.

Profile

Philip Clay Designs, based in Watford, specializes in fully bespoke British kitchen cabinetry. They thrive on high-end projects that demand exceptional attention to detail, as every project is entirely custom. Rather than mass-producing kitchens, they focus on crafting personalized elements, made specifically for each client.

Company: Philip Clay

Location: Watford, UK

Established: 2023

Employees: 15

Markets: High-End Residential, Bespoke Kitchens

CNC Machinery: Biesse