Client Story

How Microvellum & INNERGY Are Powering the Next Generation of Manufacturing Efficiency

In today’s fast-paced manufacturing environment, efficiency is everything. Businesses are constantly looking for ways to improve communication, streamline processes, and reduce errors. That’s exactly what the integration between Microvellum and INNERGY is achieving for companies like Custom Wood Products (CWP) in St. Mary’s, Kansas.

A Shift in Communication and Workflow

Before adopting INNERGY, CWP relied heavily on verbal communication and scattered notes—an approach that sometimes led to overlooked details. Today, with centralized task management, real-time collaboration, and shared notes, the team communicates more effectively across departments. This shift has created a more organized and efficient operation where critical project information is accessible to everyone who needs it, minimizing errors and keeping projects on track.

Microvellum: The Heart of the Manufacturing Process

Microvellum has played a key role in CWP’s manufacturing workflow. The software bridges the gap between design, engineering, and manufacturing by ensuring data flows seamlessly from concept to production. From shop drawings to cut lists, Microvellum empowers drafters to create and modify projects with accuracy while maintaining a high level of customization.

With Microvellum, CWP has also integrated new equipment and processes, allowing them to expand their product offerings into commercial casework and residential closets. They leveraged Microvellum’s flexibility and power to streamline their processes, saving significant time and resources.

How INNERGY and Microvellum Took CWP’s Workflow to the Next Level

Seamless Estimating & Order Processing: INNERGY’s cost-based estimating tools allow CWP to generate labor and material estimates with precision. Once an order is confirmed, it moves smoothly into production with clear visibility across teams.

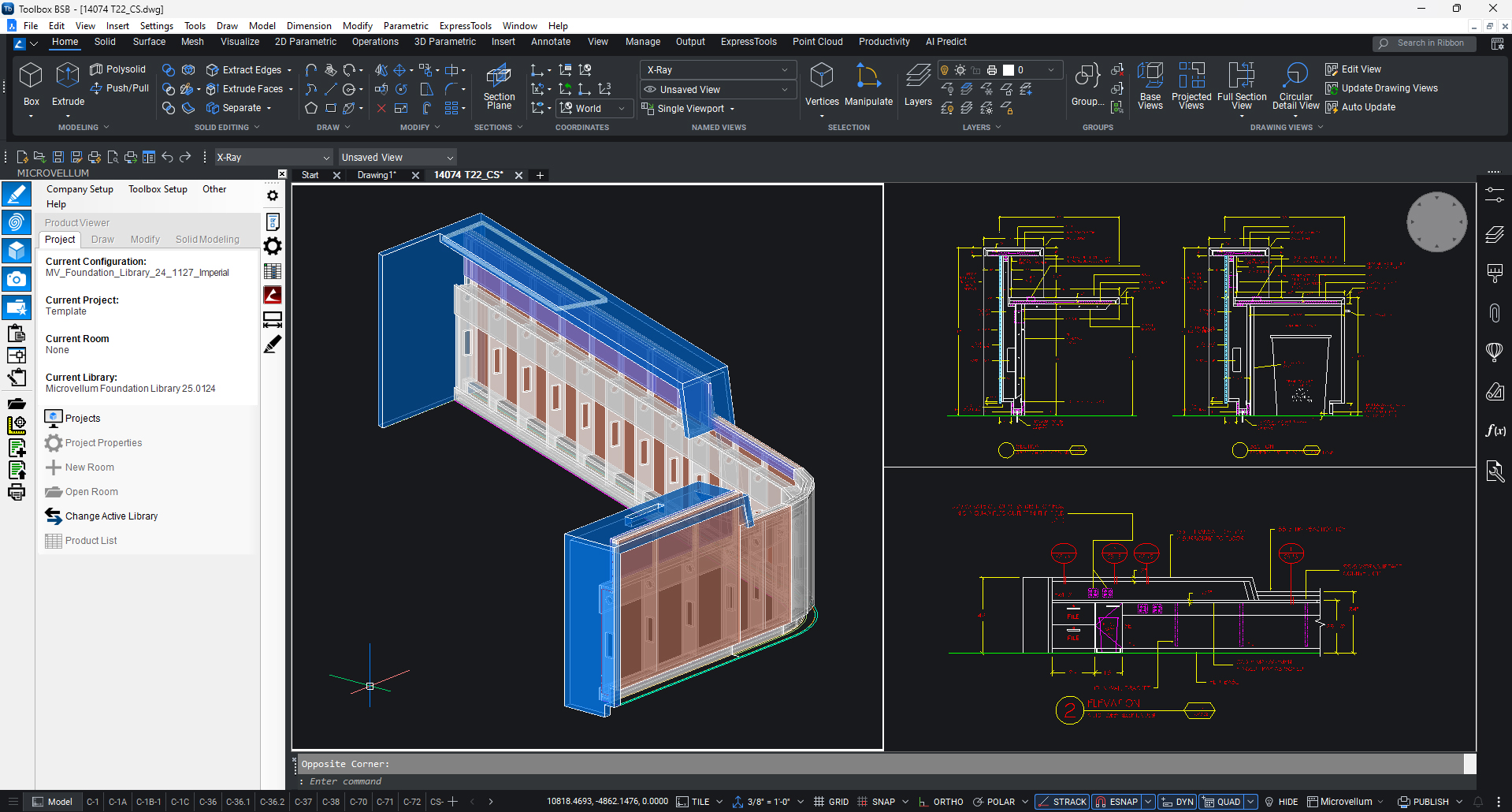

Automated Shop Drawings & Manufacturing Data: Microvellum’s powerful 2D and 3D tools and product library data are relied on to generate automatic shop drawings that incorporate real manufacturing data. This eliminates redundant work and ensures accuracy.

Real-Time Material & Inventory Management: INNERGY’s engineering link synchronizes with Microvellum’s manufacturing data, allowing CWP to track purchasing, receiving, and inventory needs. No more guessing or scrambling for materials—the system keeps everything in check.

Error Reduction & Better Forecasting: By integrating the two platforms, CWP has significantly reduced manual errors, improved communication between departments, and gained a clearer view of project timelines and material needs.

Customization for a Perfect Fit

One of the standout benefits of Microvellum’s flexibility is its ability to adapt to CWP’s specific needs. For example, the company leveraged Microvellum’s formula-driven materials feature to streamline material selection and ensure consistency across projects. Instead of manually adjusting material specs, drafters can input parameters, and the system automatically applies the correct materials, saving time and reducing mistakes.

Additionally, CWP took advantage of AutoCAD’s layer management capabilities within Microvellum to refine their drafting process. By optimizing how floor plans and elevations are displayed, they’ve eliminated the need for redundant drafting steps, helping engineers work more accurately and efficiently.

A Paperless, Streamlined Workflow

INNERGY’s integration has also helped CWP move towards a paperless workflow. Through INNERGY’s project tracking tools, drafters can submit shop drawings digitally, project managers can review them in real-time, and any necessary revisions are communicated instantly—all within the platform. No more chasing paper trails or searching for outdated files.

"We’re about as paperless as we can be now. The fact that everything—drawings, revisions, notes—is all in one place makes a huge difference," Kevin Gray.

The Road Ahead

Looking ahead, Custom Wood Products is focused on expanding its commercial casework and closet offerings while continuing to refine its use of Microvellum and INNERGY. One of the biggest improvements they’ve made is aligning naming conventions and data structures between platforms—a behind-the-scenes change that’s had a major impact.

And the results are clear: Since entering the FDMC 300 list in 2016 with $10 million in revenue and 100 employees, CWP has climbed to #151 with $50 million in revenue and a team of 345.

For manufacturers considering a similar integration, CWP’s story illustrates the power of a unified, data-driven workflow. With Microvellum driving precision in engineering and INNERGY managing projects and inventory, the company has eliminated bottlenecks, improved visibility, and reduced manual tasks. In manufacturing, efficiency isn’t optional—it’s essential.

If you're ready to modernize your operations, visit microvellum.com or INNERGY.com—or join the Microvellum Community to connect with peers and industry experts.

Profile

From a humble cabinet shop to a leading custom cabinetry manufacturer, Custom Wood Products continues to blend traditional craftsmanship with modern precision. With deep Midwestern roots and a legacy of integrity, they remain committed to helping homeowners bring their dream spaces to life—one handcrafted cabinet at a time.

Founded: 1981

Website: https://www.cwponline.com/

Annual Sales: 50 million (Ranking 151 on the FDMC 300 - 2025)

CEO: Kevin Gray

Location: Kansas, United States

Facility Size: 360,000 sq. ft.

Number of Employees: 345

Product Focus: Custom cabinetry for kitchens, bathrooms, offices, and other residential applications

CNC Machinery: Accusystem, Biesse, C.R. Onsrud, Holzma, Morbidelli, and Weeke