Microvellum sits down with son, Phil, of father-son business, Australian Commercial Cabinetry, to learn more about their company success once turning to modern technology.

Microvellum sits down with son, Phil, of father-son business, Australian Commercial Cabinetry, to learn more about their company success once turning to modern technology.

Twelve years ago, Phil Cerbu and his Dad Les, decided to put the family shed in the back yard to good use. They had an old panel saw, an edgebander, a calculator, a pencil, a ruler and the drive to build a successful joinery shop.

Today, that small-time operation has transformed into a competitive and profitable business, completing 50-60 projects per year, ranging between 60k to 750k each.

Microvellum: Thanks for taking the time out of your busy schedule to meet with us. We’ve heard a lot of good things about your company and wanted to learn a bit more to uncover the secret to your success. So, how long have you been in your new facility?

Phil: We moved into our new factory about 2 years ago, around the same time we purchased Microvellum. At that time, we only had 4 employees, but we wanted to plan for growth. We have about 680 sqm now, quite a bit bigger than our backyard shed, I’d say.

Microvellum: Honestly, that’s quite amazing to hear that you started your business out of your backyard. So, you had four employees two years ago - how many are you up to now?

Phil: When we moved to the new factory we added a fourth employee, but since then we’ve added even more. We are up to 18 full time employees. We have two designers, doing nothing but producing designs for clients, six installers out onsite most of the time and the rest of the factory is just buzzing with people. We even have the CNC running shift work just to keep up with the workload. We could not have done it without Microvellum.

Microvellum: Why did you look to Microvellum as solution for your shop?

Phil: We had multiple software systems in place before Microvellum came along, spent quite a bit of money that didn’t get us anywhere. We decided to invest in a single solution for our shop, one that would allow us to work with a single source for service and support. We were a four-man shop then, and thinking about implementing software such as Microvellum did seem a bit beyond our immediate needs, but we decided it was better to make the investment and get the best we could get. Since then, we have not had the need to purchase any other software. In fact, we had to hire more people to keep up with the amount of work flowing out to the shop.

Microvellum: I can definitely understand your frustration in dealing with separate software. I know you work with architects, so how important was an AutoCAD® solution to your business?

Phil: Let’s just say that, if Microvellum was not based in AutoCAD, I would have had to run a second software system and it would probably be in the bin with all the other software we tried. We work with a lot of architects and the people that I hire need to have backgrounds in AutoCAD, not necessarily cabinet making. It’s much easier to teach people how to use the software system to build cabinets, than it is to train them in AutoCAD.

Microvellum: You certainly knew what you wanted when you set out on your search for software for your growing shop. What about flexibility? Do you feel that the software is easy enough to use and is flexible?

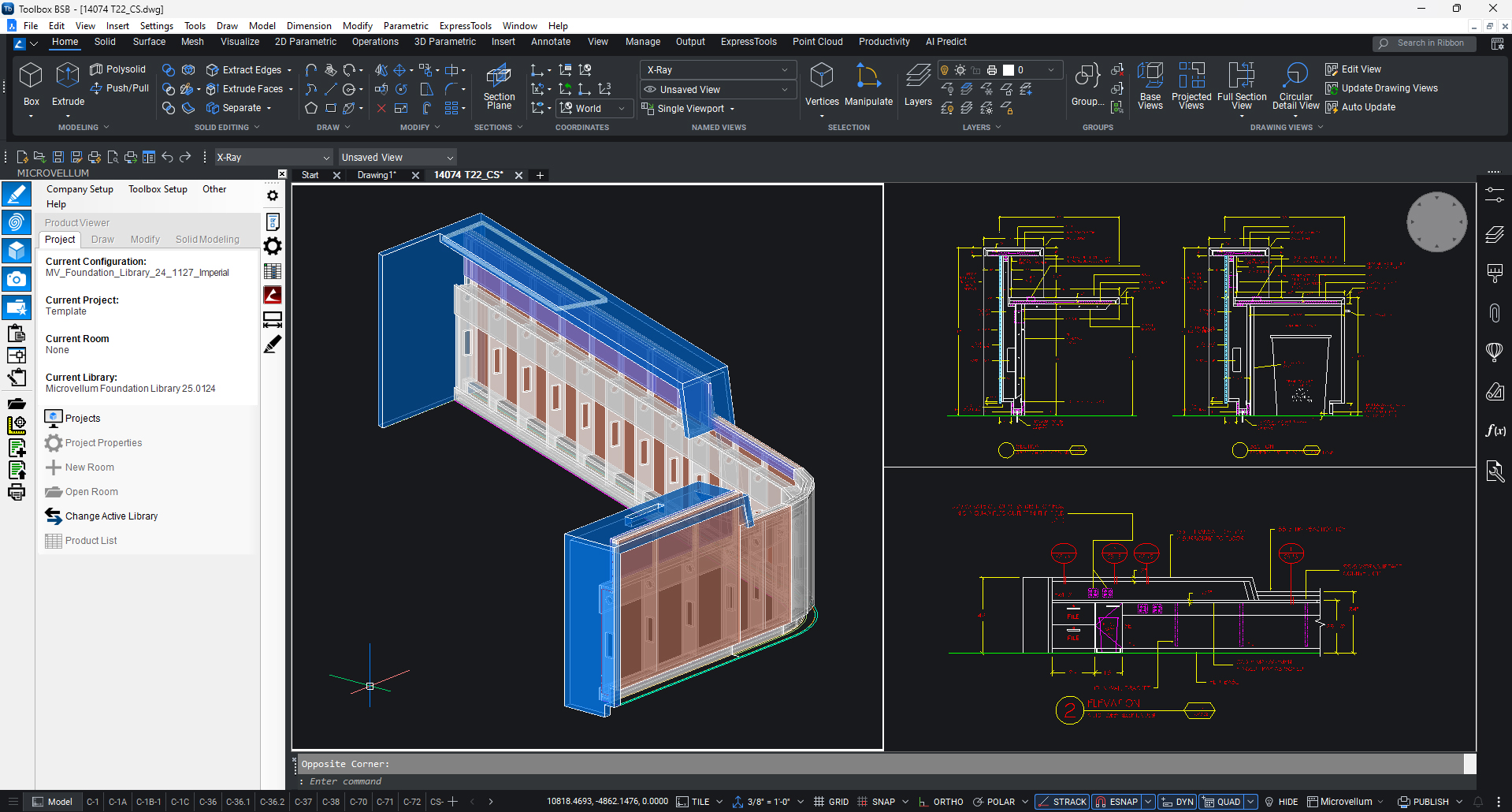

Phil: I know we’re probably not using Microvellum to the fullest and it’s capable of doing more for us, but honestly… it meets our needs daily. We create detailed designs, renderings and can create custom products all day long and push everything to the shop flawlessly. You know, at first, you may be intimidated by it, but once you’ve used the system for a while you start learning and developing new techniques that improve your workflows and design time. Training will reduce the learning curve for sure. In fact, I think the training that we had was a good reason we were able to master the software. Without it, we would have been forced to learn the ins and outs the hard way.

Microvellum: Let’s talk about the return for your investment. How long would you say that it took before you started realizing noticeable production improvements within your business?

Phil: It took about a week to become comfortable with the software, but in terms of real improvements in the shop, I’d say about four to six months. Once the contractors in our area saw that projects were getting done quickly and efficiently, without any problems, word spread quickly. One contractor spoke to another, and another and before too long, our work just exploded. To this date, we have not done one bit of advertisement, just word of mouth. Our growth has sort of been uncontrollable. Now, we are doing projects for builders that I would not have even had the opportunity to approach, all because of our capacity to get the work done.

Microvellum: Do you have a recent project that you might be able to discuss with us?

Microvellum: Do you have a recent project that you might be able to discuss with us?

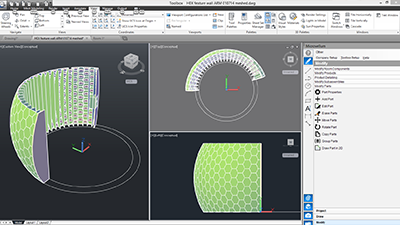

Phil: Yeah, sure… we had one a while back that was a curved feature wall with helix panels made out of laminate. There were six different colors all together. There were six other joinery shops bid for that project, but we got the project because of the software that we have. Actually, outside this job, there were several others that we got because of our software capabilities.

We had a builder contact us and ask for a feature wall. We looked at the plans, studied them and decided it could work, but we knew we had to work closely with the architect to ensure we were on track. We got a few DXF files from the architect and began our work in the software, creating each part that needed to be manufactured. We packaged all the pieces together and took it to the site for installation and to everyone’s surprise, two days later it was installed. It fit like a glove and went up perfectly the first time. Soon after the project was installed, I got a call from the architect who stated it was one of the most impressive pieces of joinery that he had ever seen.

I was confident to take on that job because I knew that I had Microvellum backing me. Without my Microvellum software, I would never had even bid on the project.

Microvellum: What about the software made the difference for you to complete this job?

Phil: I would have to say that one of the biggest advantages we had with this project is that our solution is AutoCAD-based. Being able to communicate with the architect directly, working from the same program they do to pull the DXF files from their drawings into our system to create renderings and cut parts is such a benefit for us. We’re able to see the project in 3D to verify tolerances and trust that when the wall was built, it would actually go together onsite. Then, when we were ready to manufacture it, Microvellum created the machine code for my Holz-her CNC and the rest went together flawlessly.

Microvellum: After reviewing the photos of that project, I must say that is one impressive piece of joinery. Is there anything else that you’d like to add?

Phil: We have a lot of opportunities coming in the near future. Times are changing and to stay competitive you have to keep up with changes. I know just five years ago, you could get by without a CNC and maybe even without software. Now, no one would even take you seriously if you didn’t have at least one CNC being driven by software like Microvellum.

Microvellum: Thanks for your time today and congratulations on all your success! We appreciate the opportunity to play our part and wish you the best in all your future projects.

About Australian Commercial Cabinetry

Based in Victoria, with over 20 years' experience, Australian Commercial Cabinetry comes from humble beginnings, and has grown into a successful manufacturer - with the latest machinery and software to meet its client's' expectations.

Learn more about Australian Commercial Cabinetry.